The company

On 01/06/2011, was inaugurated in Brazil the company BINSIT COMPONENTES AUTOMOTIVOS LTDA. Located in São Leopoldo/RS, BINSIT was created to meet the demand for thermoplastic parts made by injection blow process in Brazil. The company comes from the association of italian INSIT INDUSTRIA s.p.a., with over 20 years of technological expertise in manufacturing thermoplastic boots with Ossberger process, and BINS INDÚSTRIA DE ARTEFATOS DE BORRACHA LTDA, recognized for outstanding knowledge and experience in the Brazilian market of rubber parts for the automotive sector.

The synergy of both companies, has enabled a new facility in Brazil, which now in its second year of operation has become a reference in the production of boots for CVJ sideshafts and steering mechanisms, result of the seriousness and technological knowledge of their shareholders.

Due to the fast expansion of its business, there was a need to expand our manufacturing facilities at the end of 2014, where the company then migrated to a new plant, also in

the city of São Leopoldo- RS, capable of operating with up to 10 machines injection-blow machines.

In the first half of 2018 BINSIT occurred the split with the company BINS Indústria de Artefatos de Borracha Ltda, taking over GRAN Indústria e Reciclagem de Borracha Ltda, that belongs to the Bins family, with a long tradition in the automotive segment and with expertise in the manufacture of thermoplastic products and thermosets, remaining associated with INSIT Industria SpA, who has a strong presence in the European market. In Brazil, we have nearly 50% of the market share in the family of boots for

homocinetic sideshafts.

Technology

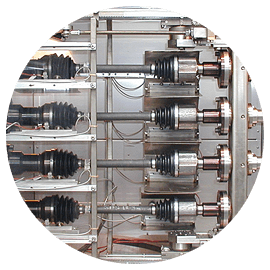

BINSIT manufactures its products using the injection blow technology of the German manufacturer OSSBERGER. Machines are equipped with high level of automation that provides precision and repeatability of the process. In conjuction, we use peripheral equipments with the latest technology to supply and dehumidificate our raw materials, ensuring that our products maintain the original properties of their respective materials, thus making our process more stable and our products more robust.

In our plant, the production process is carried out in an air-conditioned area, with temperature and relative humidity

control, so that the process is not influenced by climatic oscillations and thus making it

more reliable. All our products undergo weight control and visual inspection, besides the regular

dimensional control. We have a wide range of devices and measuring and control instruments,

to ensure that all requirements of the product and the process will be achieved.

Quality

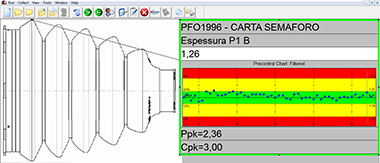

BINSIT has a certified quality management system according to IATF 16949:2016 standard. Moreover, BINSIT adopts the same criteria of quality control developed in Italy over more than 30 years of evolution of the injection blow technology, with the immediate support of a highly qualified technical team and advanced resources to prevent potential problems. Additionally, BINSIT uses a modern structure of validation tests at INSIT to perform life tests on CVJ boots for sideshafts.

Products

The products manufactured by BINSIT are allocated for OEM Market. In Brazil, the company has technology capable for manufacturing 3 products families:

-

Boots for CVJ sideshafts:

-

Bellows for steering mechanisms

-

Jounce bumpers

-

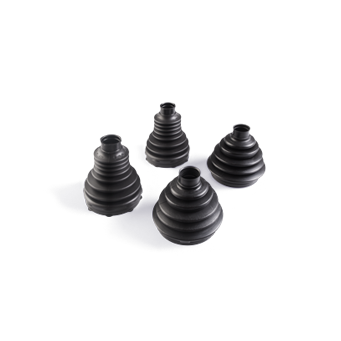

Boots for CVJ sideshafts:

The CVJ sideshaft is a system that transfers torque from the differential to the wheels, moving the wheel according to the movement of the steering or suspension. The bellows keep the lubricant in the joint and prevent dirt and other contaminants from entering.

The bellows for CVJ sideshafts are manufactured by BINSIT with thermoplastic resins (TPE-E). The thermoplastic materials have advantages like greater durability, lower final part weight, and are 100% recyclable.

-

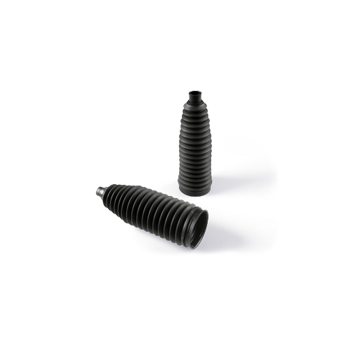

Bellows for steering mechanisms

In the past the bellows for steering mechanisms were made with rubber compounds, but nowadays, we use thermoplastic material (TPV), which offers benefits such as increased durability, increased strength, lower weight and 100% recyclable material.

The steering mechanism transmits the rotation movement of the steering wheel to the vehicle’s wheels, allowing safe and comfortable maneuvers. In the case of the hydraulic steering mechanism, the additional hydraulic power provided improves the safety and comfort features even further. The bellows seals the rack and prevents contamination or the entry of dirt.

-

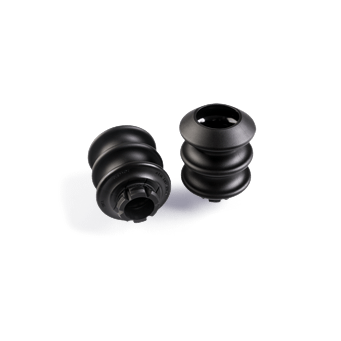

Jounce bumpers

It is an innovative solution, a component of the upper bumper that aims to prevent the impact at the end of the compression spring metal. The jounce bumper was developed as an alternative to the current solution of polyurethane foam, having the following advantages: thermoplastic material (TPE-E); good resistance to low temperature; high resistance to fatigue wear; does not absorb moisture; constant deflection at maximum load; reduction in weight; and recyclable material.

Clients

Contact

Please contact us if you have questions and/or are interested in more information about our company or products: